How much better would your long haul operations operate with Optiyol's smart logistics solutions?

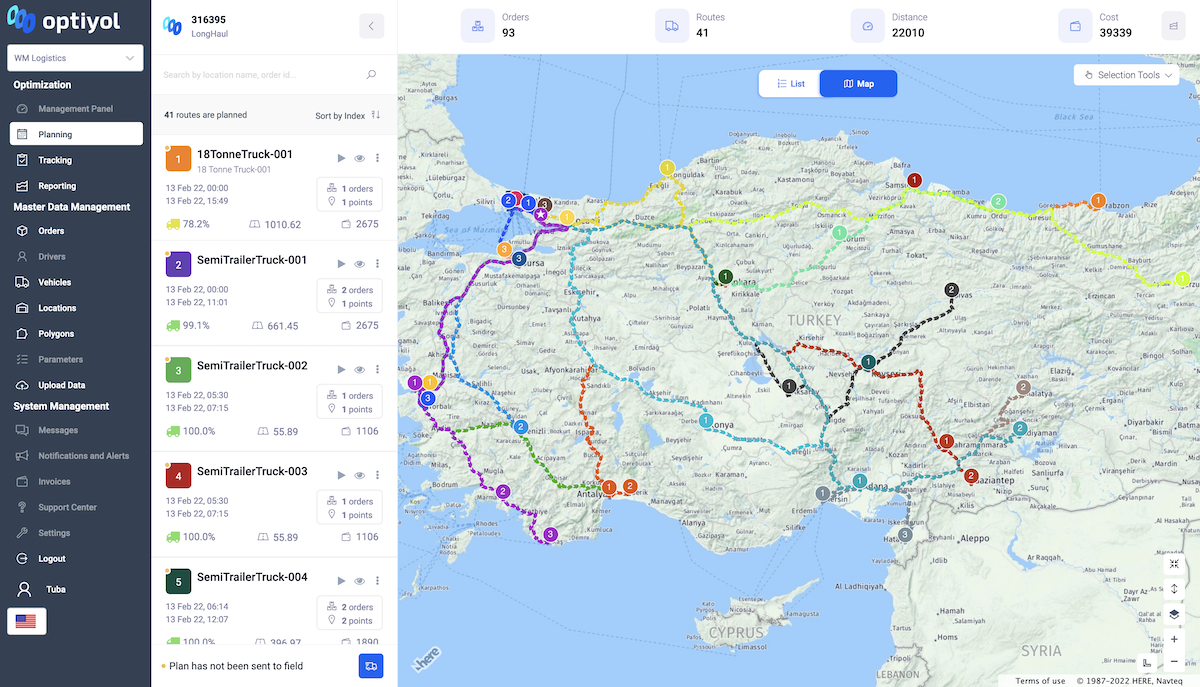

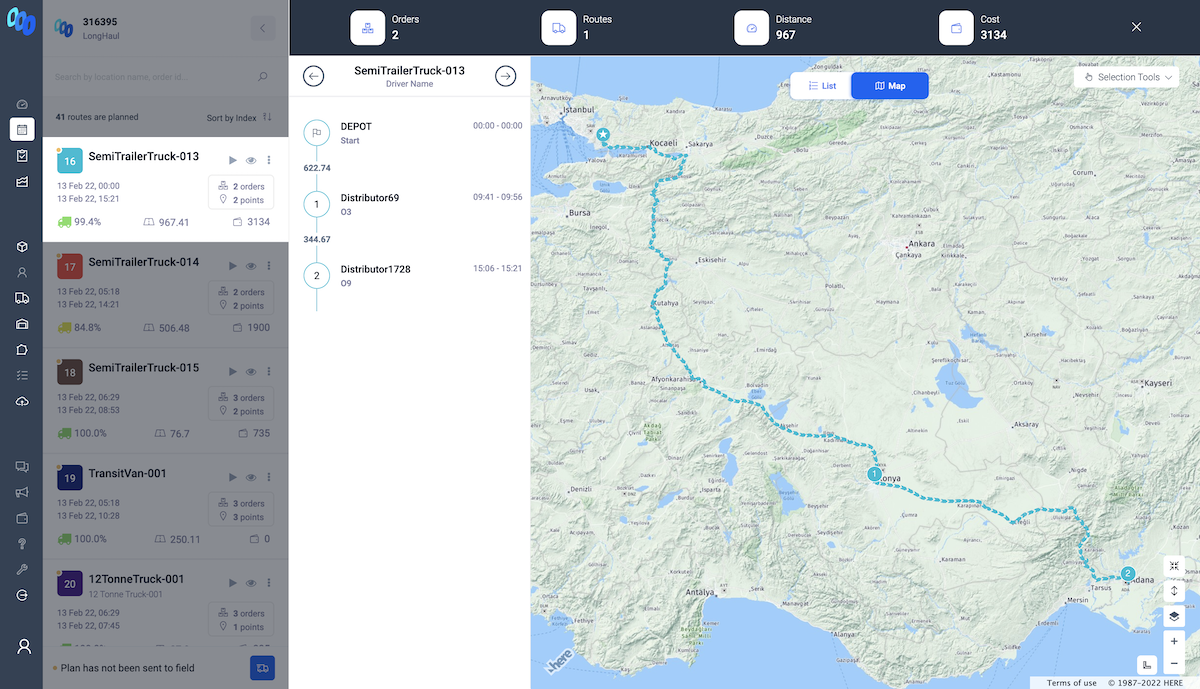

DISCOVER THE PRODUCT REQUEST A DEMOLong-haul operations generally cover inter-city transportations from a central distribution center to regional warehouses with large trucks. The planning challenge is to consolidate orders to different routes with minimal cost while respecting delivery time commitments, capacities, and vehicle type restrictions. Route planning determines how to allocate orders to each transportation mode (FTL, LTL, Direct/Crossdock, etc.) and routes for FTL orders. But manual efforts may fail to accomplish every goal of your operations. Optiyol offers a rapid return on investment through a modular and tunable algorithm design that can quickly create tailor-fit models and realistic route plans in all your intercity operations. Try a cost-efficient solution to deliver the best service to both your commercial and residential customers.

With the ever-growing e-commerce and expansion of transport networks, residential long haul operations became a part of transportation of goods. The demand has been transforming towards more direct and faster service to consumers in macro deliveries too. And, most of the consumers require a promised time slot to make sure they will not spend the whole day at home waiting for their goods to be delivered. Without automating and optimizing your residential long haul services, you will not only miss saving on costs, but you may also fail to create customer satisfaction. By understanding your needs at every step, Optiyol offers dynamic route optimization for your intercity residential deliveries.

In your commercial long-haul deliveries, products move over complex networks such as raw material depots, manufacturing plants, central and regional warehouses, and cross docks until reaching the final retail points. These stores can be visited based on dynamic orders or based on pre-agreed weekly or monthly frequencies. Hence, smooth operations are crucial for cost-efficiency when it comes to commercial intercity goods transportation. Optiyol enables on-time and low-cost logistics for shippers and carriers so that they can thrive in long-haul supply chain operations. With Optiyol, you can simulate planning and running simulations with historical or forecasted order data to calculate estimated costs of transportation under different pricing scenarios for FTL and LTL options.

Optiyol's optimization algorithms have been a game changer for our fleet management! Their high accuracy and customization capabilities consistently deliver the best routes tailored to our unique constraints and priorities, reducing fuel costs and delivery times - transforming our operations into a more cost-effective and efficient process.

Ersin Dilbaz

We are working with Optiyol to optimize our customer deliveries. Optiyol takes into account all the constraints and preferences of our delivery operations, allowing us to make timely deliveries to more locations with fewer resources. With its strong team, Optiyol provides excellent quality service.

Hakan Çırpanlı

Optiyol has been a game-changer for Beymen. Their optimization algorithms have significantly improved our workflow efficiency. Managing vehicle routes has never been easier and they have greatly assisted us in solving our last mile delivery issues. I highly recommend Optiyol for any business looking to improve productivity in their operations.

Alper Uca

Hayat Kenya is our first subsidary for which we succesfully implemented Optiyol that is a cloud based route optimization software. During the project we experienced remarkable efforts, observed customer focus and achieved notable results. I advise this flexible tool to be absolutely considered for sustainable smart route optimization needs.

Kürşat Erdoğan

Our dream came true after we met with Optiyol. We work together to optimize our distribution operations. With Optiyol, it is now possible to plan the operations at the same level of expertise, everywhere.

Uğur Duman